What is the difference between sanitary filters and strainers? Filters use disposable media to capture fine particles, while strainers are equipped with a reusable wire mesh screen that removes the larger particles. These components serve vital purposes at different points along the production line. Sanitary inline strainers tend to be used at the earliest stages of processes, where there is a higher potential for large particulates to be present in the flow. These must be caught and removed before they find their way into equipment and damage it. Filters, on the other hand, tend to be integrated into the later stages of processing. This is because the fluid already has gone through strainers and should be free from large-scale contaminants. The use of sanitary filters at this stage traps finer particulates that are likely to have a negative effect on the quality of the finished products.

Why Choose Steel & O’Brien?

Steel & O’Brien offers inline and side-inlet stainless steel sanitary strainers and filters to meet a range of needs. Regardless of what is being processed, the temperature and operating pressure (up to 100 psi), the line size and connection type, you’re sure to find the best product for your application in our vast inventory.

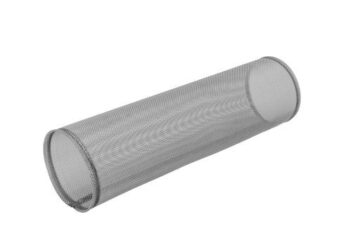

Our products easily convert from strainer to filter, are 3-A certified (without mesh), and have interchangeable parts to minimize your inventory requirements. Backup tubes with 1/4” perforations and 9 holes per square inch are standard; 1/8” perforations are available. Made from 316 stainless steel, we offer short and long models, narrow models and wide models. Filter media and dual strainer stands are also available. These products are just one more way in which we make sanitary simple through superior service for our customers. Our tri-clamp strainers and filters are made to the same high standards as all our stainless steel components, providing you with the best possible performance and the highest-quality products.