Frequently Asked Questions

Why is stainless steel preferred for data center liquid cooling connectors and components?

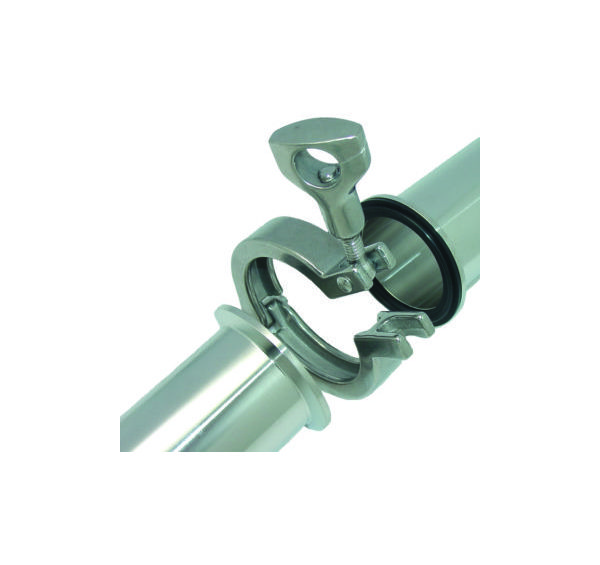

Stainless steel has rapidly become the preferred material for many data center liquid cooling components due to its hygienic properties, coolant compatibility, durability, and cost-effectiveness.

Learn More Here

How long has Steel & O’Brien been providing stainless steel flow components?

For over 30 years, we have been designing, engineering, and manufacturing sanitary fittings, valves, and custom components from stainless steel. Our expertise lies in meeting the strict sanitary standards required for food, beverage, and pharmaceutical production. In the past five years, we have expanded our capabilities to also specialize in the data center liquid cooling market.

What type of experience does Steel & O’Brien have with data center cooling?

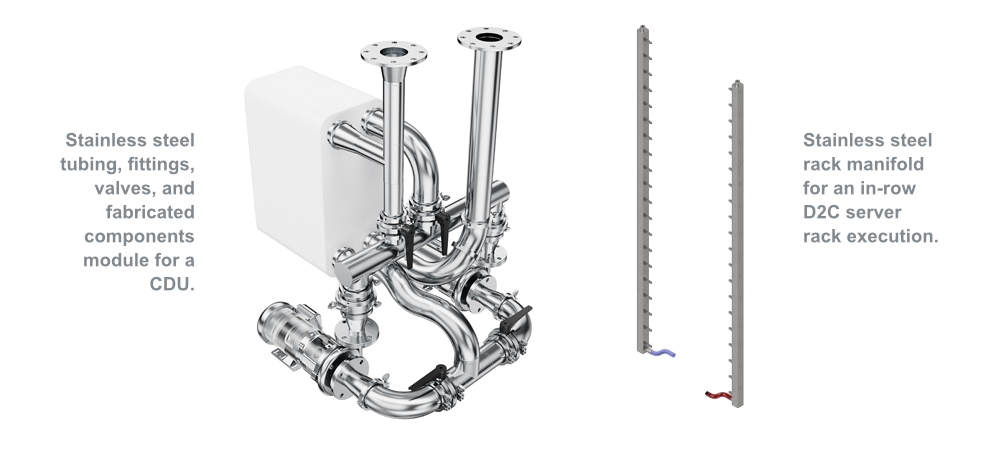

We specialize in providing solutions for data center liquid cooling systems and related infrastructure, including rear-door heat exchangers, direct-to-chip (D2C) cooling, and immersion cooling systems, for both hyperscale and colocation data centers. Our comprehensive range of stainless steel products can be found throughout data centers in Coolant Distribution Units (CDUs), rack manifolds, circulation loops, and infrastructure piping.

What are Steel & O’Brien’s capabilities and capacity for serving data center liquid cooling customers?

Our 200,000 sq. ft., ISO Certified manufacturing facility has the capabilities and capacity to produce custom stainless steel components for data center cooling installations in high volume. We have deep expertise machining, fabricating, welding, and polishing stainless steel that is enhanced by our in-house engineering resources for customer specified designs, including CDU components and manifolds used in liquid cooling systems.

If you can’t find the exact data center cooling configuration or specifications for your application, there’s no need to worry. Our extensive custom machining and fabrication capabilities allow us to create tailored solutions to meet your needs. This is just one way we simplify the process through exceptional service. By choosing Steel & O’Brien, you’ll benefit from our comprehensive expertise, ensuring the solution that best suits your operations.